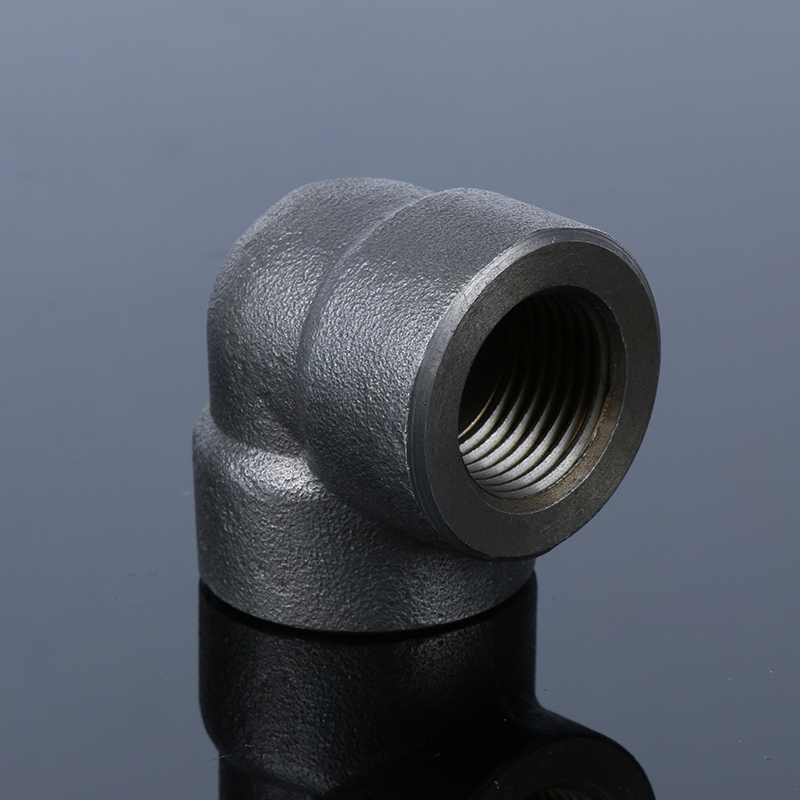

产品描述

| Threaded Elbow Specifications: | |||||||||||||||

| Size/尺寸 | 1/8″~4″ (DN6~DN100) | ||||||||||||||

| Class/压力等级 | 2000 LBS, 3000 LBS, 6000 LBS | ||||||||||||||

| Type/连接形式 | Threads: American National Standard Taper Pipe Threads, | ||||||||||||||

| NPT(ANSI/ASME B1.20.1-1983), | |||||||||||||||

| Also available in other thread forms: Rc, Rp, BSP, BSPT,BSPP and in any combination. | |||||||||||||||

| Surface Treatment/表面处理 | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Soldering,Darken, | ||||||||||||||

| 热浸镀锌,环氧树脂和FBE涂层,电抛光,喷砂,发黑 | |||||||||||||||

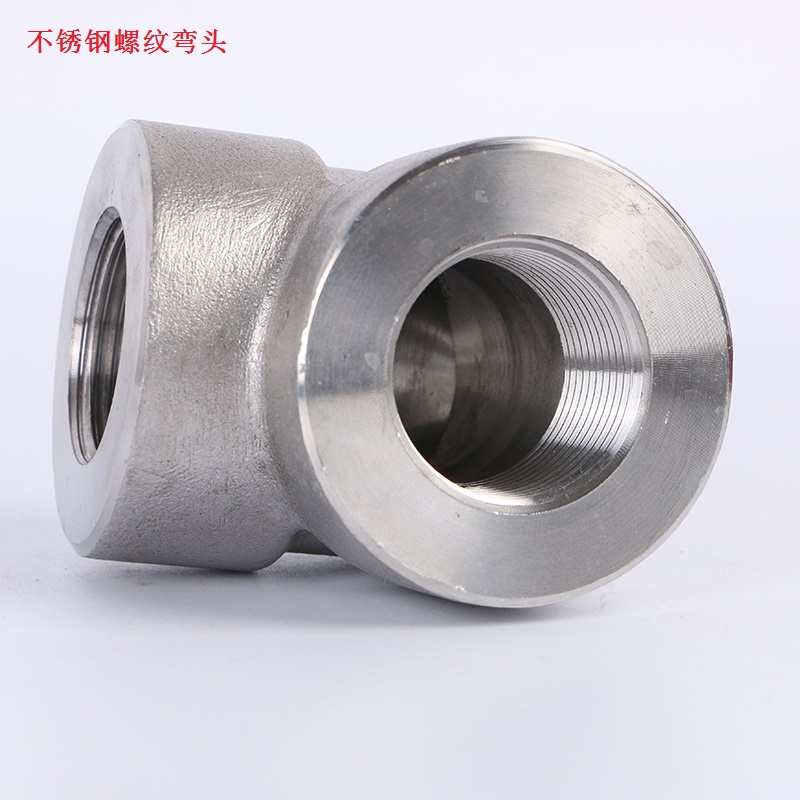

| Materal/材质 | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel | ||||||||||||||

| Manufacturing process/制造工艺 | Cutting, Heat treatment, Forging, Machining, | ||||||||||||||

| 锯切、热处理、模锻、机加工 | |||||||||||||||

| Manufacturing Standards/制造标准 | ASME 16.11, GB/T14383-2018,BS-3799 | ||||||||||||||

| Threaded Elbow Material Grades: | |||||||||||||||

| Stainless Steel/不锈钢 | ASTM A182 F304, 304L, 316, 316L,310S, 316Ti,317L | ||||||||||||||

| Duplex & Super Duplex Steel/双相钢 | ASTM A 182 – F51, F53, F55, S31803, S32205, S32550, S31254, SMO254, S32750, S32760, S32950. | ||||||||||||||

| Carbon Steel/碳钢 | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2 | ||||||||||||||

| Alloy Steel/合金钢 | ASTM / ASME A 182, ASTM / ASME F5, F9, F11,F22, F 91 | ||||||||||||||

| Copper Alloy Steel/铜合金 | Copper Alloy Steel Forged Threaded 90 Deg Elbow : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30) | ||||||||||||||

| Nickel Alloy/镍合金 | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) | ||||||||||||||

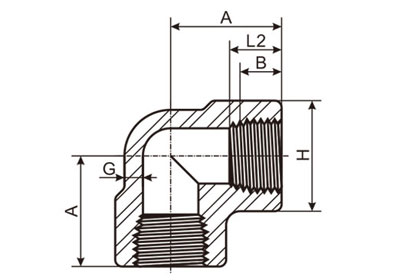

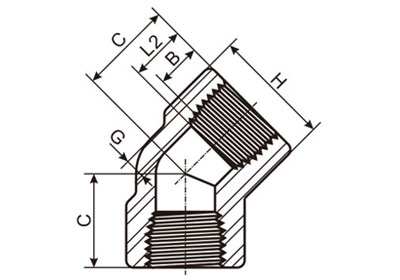

| Threaded Elbow Dimesions: | |||||||||||||||

| 90°螺纹弯头 | 45°螺纹弯头 | ||||||||||||||

|

|

||||||||||||||

| Threaded Pressure Class | Pipe Schedule | ||||||||||||||

| Class 2000 | S80/XH | ||||||||||||||

| Class 3000 | S160 | ||||||||||||||

| Class 6000 | XXH | ||||||||||||||

| DN | Nom. | Center to End | Center to End | Outside Diameter | Minimum Wall | Length Of | |||||||||

| Pipe | Elbow,Tee,Cross | 45°Elbow | Of Band | Thickness | Thread | ||||||||||

| Size | A | C | H | G | Min.(1) | ||||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | B | L2 | ||

| 6 | 1/8" | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4" | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.3 | 6.6 | 8.1 | 10.2 |

| 10 | 3/8" | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2" | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4" | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1" | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1-1/4" | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17 | 18 |

| 40 | 1-1/2" | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2" | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 84 | 102 | 4.27 | 7.14 | 12.09 | 19 | 19.2 |

| 65 | 2-1/2" | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3" | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4" | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33 |

| (1) Threaded End ASME B16.11-2009(Revision of ASME B16.11-2005). | |||||||||||||||

| (2) Dimensions in Millimeters. | |||||||||||||||

| (3) Dimension B is minimum length of perfect thread. The length of useful thread(B plus threads with fully formed roots and flat crests)shall not be less than L2(effective length of external thread)required by American National Standard for Pipe Threads (ANSI/ASME B1.20.1) |

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

版权所有:河北中燃管道有限公司 冀ICP备19004948号-6

热线:0317-6165555

热线:0317-6165555 9905791@qq.com

9905791@qq.com