产品描述

| Socket Weld Tee Specification: | |||||||||||||||||||||

| Size/尺寸 | 1/8″~4″ (DN6~DN100) | ||||||||||||||||||||

| Class/压力等级 | 3000 LBS, 6000 LBS, 9000 LBS | ||||||||||||||||||||

| Type/连接形式 | Sockeweld,承插焊 | ||||||||||||||||||||

| Surface Treatment/表面处理 | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Soldering | ||||||||||||||||||||

| Materal/材质 | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel | ||||||||||||||||||||

| Manufacturing process/制造工艺 | Cutting, Heat treatment, Forging, Machining,锯切、热处理、模锻、机加工 | ||||||||||||||||||||

| Manufacturing Standards/制造标准 | ASME 16.11, GB/T14383-2018,BS-3799 | ||||||||||||||||||||

| Socket Weld Tee Material Grades: | |||||||||||||||||||||

| Stainless Steel/不锈钢 | ASTM A182 F304, 304L, 316, 316L,310S, 316Ti,317L | ||||||||||||||||||||

| Duplex & Super Duplex Steel/双相钢 | ASTM A 182 – F51, F53, F55, S31803, S32205, S32550, S31254, SMO254, S32750, S32760, S32950. | ||||||||||||||||||||

| Carbon Steel/碳钢 | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2 | ||||||||||||||||||||

| Alloy Steel/合金钢 | ASTM / ASME A 182, ASTM / ASME F5, F9, F11,F22, F 91 | ||||||||||||||||||||

| Copper Alloy Steel/铜合金 | Copper Alloy Steel Forged Threaded 90 Deg Elbow : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30) | ||||||||||||||||||||

| Nickel Alloy/镍合金 | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) | ||||||||||||||||||||

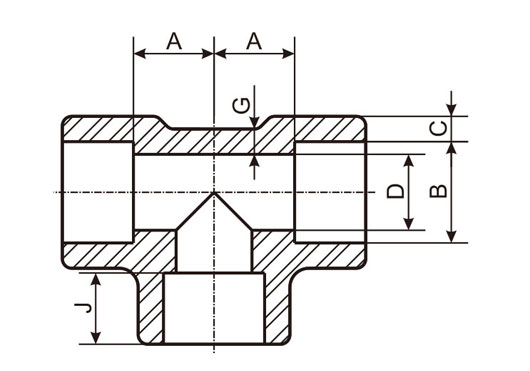

| Socket Weld Tee Dimesions: | |||||||||||||||||||||

|

|||||||||||||||||||||

| Socket Weld Pressure Class | Pipe Schedule | ||||||||||||||||||||

| Class 3000 | S80/XH | ||||||||||||||||||||

| Class 6000 | S160 | ||||||||||||||||||||

| Class 9000 | XXH | ||||||||||||||||||||

| DN | Nom. | Center to Bottom of Socket-A | Socket | Bore Dia.Of Fitting | Socket Wall Thickness(2) | Body Wall Thickness | Depth | ||||||||||||||

| Pipe | Bore | D | C | G | of | ||||||||||||||||

| Size | 90°Elbows | 45°Elbows | Dia. | Class Designation | Class Designation | Socket | |||||||||||||||

| Tees,Crosses | B | Min. | |||||||||||||||||||

| Class Designation | Class Designation | Class Designation | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | J | ||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Ave. | Min. | Ave. | Min. | Ave. | Min. | Min. | Min. | Min. | ||||

| 6 | 1/8" | 11 | 11 | --- | 8 | 8 | --- | 10.8 | 6.9 | 4 | --- | 3.18 | 3.18 | 3.96 | 3.43 | --- | --- | 2.41 | 3.15 | --- | 9.5 |

| 8 | 1/4" | 11 | 13.5 | --- | 8 | 8 | --- | 14.2 | 9.3 | 6.4 | --- | 3.78 | 3.3 | 4.6 | 4.01 | --- | --- | 3.02 | 3.68 | --- | 9.5 |

| 10 | 3/8" | 13.5 | 15.5 | --- | 8 | 11 | --- | 17.6 | 12.6 | 9.2 | --- | 4.01 | 3.5 | 5.03 | 4.37 | --- | --- | 3.2 | 4.01 | --- | 9.5 |

| 15 | 1/2" | 15.5 | 19 | 25.5 | 11 | 12.5 | 15.5 | 21.8 | 15.8 | 11.8 | 6.4 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 |

| 20 | 3/4" | 19 | 22.5 | 28.5 | 13 | 14 | 19 | 27.2 | 21 | 15.6 | 11.1 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 |

| 25 | 1" | 22.5 | 27 | 32 | 14 | 17.5 | 20.5 | 33.9 | 26.7 | 20.7 | 15.2 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 |

| 32 | 1-1/4" | 27 | 32 | 35 | 17.5 | 20.5 | 22.5 | 42.7 | 35.1 | 29.5 | 22.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 |

| 40 | 1-1/2" | 32 | 38 | 38 | 20.5 | 25.5 | 25.5 | 48.8 | 40.9 | 34 | 28 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 |

| 50 | 2" | 38 | 41 | 54 | 25.5 | 28.5 | 28.5 | 61.2 | 52.5 | 42.9 | 38.2 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 |

| 65 | 2-1/2" | 41 | --- | --- | 28.5 | --- | --- | 73.9 | 62.7 | --- | --- | 8.76 | 7.67 | --- | --- | --- | --- | 7.01 | --- | --- | 16 |

| 80 | 3" | 57 | --- | --- | 32 | --- | --- | 89.8 | 78 | --- | --- | 9.52 | 8.3 | --- | --- | --- | --- | 7.62 | --- | --- | 16 |

| 100 | 4" | 66.5 | --- | --- | 41 | --- | --- | 115.2 | 102.3 | --- | --- | 10.69 | 9.35 | --- | --- | --- | --- | 8.56 | --- | --- | 16 |

| (1) Dimensions in Millimeters. |

| (2) Average of socket wall thickness around periphery shall be no less than listed values. The minimum values are permitted in localized areas. |

| (3) Upper and lower values for each size are the respective maximum and minimum dimensions. |

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

版权所有:河北中燃管道有限公司 冀ICP备19004948号-6

热线:0317-6165555

热线:0317-6165555 9905791@qq.com

9905791@qq.com